Drawing on the lessons learned from the Great East Japan Earthquake, in February 2013 FANCL Group formulated a Business Continuity Plan (BCP) to minimize potential damage and enable the delivery products to customers as quickly as possible in the event of an earthquake directly under the Tokyo metropolitan area, which is predicted to have a significant impact on our business. However, in addition to earthquakes, in recent years other disasters have been increasing year by year, including windstorms and floods, infectious diseases such as COVID-19, and IT failures caused by cyberattacks, and the damage has become increasingly significant. In light of this situation, from 2021 we have working to restructure our BCP to cover our response to all types of potential hazards.

In 2010, we introduced a safety check system for employees, and as a result of repeated drills, we have been able to create a system that enables us to quickly confirm the safety of all Group employees with a 100% participation rate. In 2012, all Group sites were fully stocked with disaster stockpiles (food, toilets, bedding, and daily necessities), and a system was put in place that would enable employees to stay overnight at our facilities if they are unable to return home. We have also prepared a Group-wide disaster manual. In addition, we are working to raise awareness of disaster preparedness at home, including recommending keeping disaster supplies in the home and checking local hazard maps, and since 2019, we have been selling company-recommended disaster supplies to employees every year, with shipping costs covered so that they can send them to family and friends in distant locations.

Report on the Implementation of the Kanagawa Shakeout

Since 2013, FANCL has been participating in "The Great Kanagawa ShakeOut,” a simultaneous disaster preparedness drill organized by Kanagawa Prefecture,.

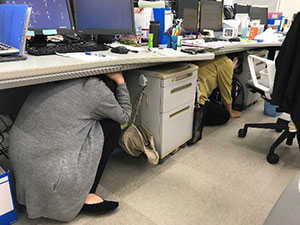

On September 5, 2022, approximately 1,000 employees from four Group sites (Head Office Building, Research Institute, FANCL Biken Yokohama Plant, and Iijima Building) participated in the drill. Remote employees participated from their homes.

This is the ninth time that FANCL has participated in this disaster drill, which is attended by more than 1.6 million people throughout Kanagawa Prefecture.

Unlike most disaster drills that gather participants at a training site, the "Kanagawa Shakeout" is a drill in which participants learn to protect themselves, and are told to 1. DROP! (get down), 2. COVER! (protect the head!), and 3. HOLD ON! (do not move).