In response to issues surrounding marine plastics, we have begun efforts to reduce the amount of plastic used in our business, such as in the manufacturing of containers.

Targets

-

Sustainable containers and packaging based

on the 4 Rs※1By FY Mar/2031100%(FY Mar/2023 : 50.9%)

-

Rate of use of plant-derived or recycled plastic

for FANCL cosmetics containersBy FY Mar/2031 30%(FY Mar/2023 : 40.1% Achieving our goals)

-

Adoption of environmentally friendly

paper※2 in paper-based container packagingBy FY Mar/2026100%(FY Mar/2023 : 85.2%)

- 1 Reduce (reduction in the amount of plastic used for our containers), Reuse (reuse of containers), Recycle (recycling of container recovery), Renew (switch to recycled or plant-based materials)

- 2 Certified paper, non-wood paper, recycled paper, etc.

- Sustainable packaging based on the 4Rs, plant-based and recycled plastics used in FANCL cosmetics, and use of certified palm oil apply to cosmetics and health foods of FANCL CORPORATION and ATTENIR CORPORATION.

Our basic policy for reducing plastic in containers and packaging

The FANCL Group is working with customers to reduce the amount of plastic used in containers and packaging, to achieve a decarbonized, recycling-oriented society. We have actively promoted "Reduce and Reuse" and have achieved a reduction in plastic use.

To maintain the Mutenka quality that is a feature of our products, we strive to reduce environmental impact as much as possible by adopting a renewable perspective when using plastic materials for sealed containers.

From the fiscal year ended March 2022 we began collecting and recycling cosmetic containers to help achieve a recycling-oriented society.

In the future, we will strengthen cooperation with the Kirin Group, with which we have entered into a capital and business alliance, and work toward the realization of closed-loop recycling, in which collected cosmetic containers are recycled as raw materials for cosmetic containers.

Initiative report

REDUCE

We are reducing our plastic use by reducing the weight of containers and changing the container material from plastic to paper.

A lighter container for our Mild Cleansing Oil

We have gradually cut back the weight of our Mild Cleansing Oil bottles by reducing the bottle plastic by about 40% (compared with 2004).

Reductions to the amount of plastic used in supplement products' aluminum pouch bags

FANCL has started to use aluminum pouch bags to hold its health food products. As we strive to sell healthy foods at reasonable prices, we have adopted aluminum pouch bags in place of plastic bottles to reduce manufacturing costs. In 2013, we succeeded in reducing the thickness and weight of these aluminum pouch bags by 11% and 5%, respectively.

We are also currently working to reduce the standard size of the packaging itself.

In addition, we are switching from using gusseted bag packaging (plastic outer bags with gussets) to instead using decorative boxes made of environmentally friendly forest-certified paper. We aim to replace all of these products by the fiscal year ending March 2024. By making this changeover to paper decorative boxes, we expect to be able to reduce the amount of plastic used by 5.6 tons.

Switching from wholesale plastic packaging to paper

From late March 2023, we will gradually switch from using conventional plastic packaging for skincare products sold wholesale at drugstores and convenience stores, to eco-friendly forest-certified paper packaging. This move will cover 6 products (a total of 9 varieties). By making this changeover to paper packaging, we expect to be able to reduce the amount of plastic used by about 92 tons.

A first for the domestic cosmetics industry! Development of cosmetic packaging materials from beer by-products

(Switching from plastic to hemicellulose)

At FANCL we sell refills for products such as our solid foundation product that allow the repeated use of the same compact case.

These refills have used blister packaging※1 made from conventional PET plastic. However, in the fiscal year ended March 2023 in collaboration with Kirin's Package Innovation Research Institute, we began developing a sheet using hemicellulose※2 extracted from beer lees, a byproduct of the brewing of Kirin Ichiban Shibori Draft Beer. This has led to the commercialization of plant-derived refill blister packaging.

Through this changeover, we expect to be able to reduce the annual amount of plastic used by approx. 1.6 tons.

- Blister packaging: Packaging produced by a manufacturing method in which a heated and softened sheet is molded in a die

- Hemicellulose A general term for water-insoluble polysaccharides (other than cellulose) found in plant cell walls

REUSE

We sell environmentally friendly refills while maintaining product quality.

FANCL Cosmetics refillable containers

By replacing formerly used bottle-type packaging with refillable packaging, we have significantly reduced the amount of resin used during the manufacturing process, contributing to an overall reduction of plastic waste.

We have also started using refillable containers for special care items while maintaining Mutenka quality, thereby contributing to the reduction of plastic waste.

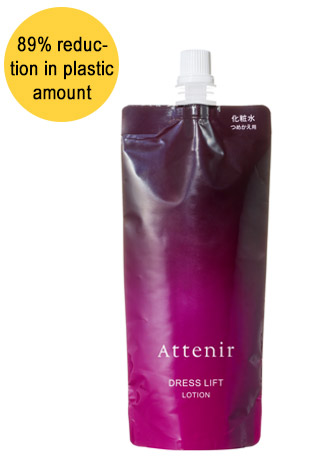

Attenir refill containers (eco packs)

Attenir has been working to commercialize refillable containers (eco packs) since 1995, spurred on by customers who have spoken up about the waste resulting from having to throw away containers after a single use.

For our skincare products, we also have a lineup of eco pack holders and products that can be easily refilled with a single touch. We have succeeded in reducing the amount of plastic used for our refillable Skin Clear Cleanse Oil Eco Pack by about 85% since doing away with the bottle-type container.

Attenir Bright Inception, which was newly released in March 2023, uses a refillable container that enables a reduction in the amount of plastic by 63%※. The specification for this container has evolved, making the empty refill easy to take out and the new one easy to load. The refill can be used until all its contents are gone.

In a comparison between Attenir White Genesis serum and the new refill

RECYCLE

We collect and recycle used cosmetic containers.

The FANCL Recycle Program for containers

The FANCL Recycling Program is an initiative that collects used cosmetic containers from customers at stores nationwide, separates, cleans, dries, and crushes the containers at FANCL SMILE※1 (a special subsidiary), and then recycles them into flower pots at a partner recycling company. The flower pots are donated to Yokohama City, where FANCL's head office is located. They are being used by local residents, at the flower and green event Garden Necklace Yokohama, and in environmental education at elementary schools in the city.

This initiative, which started at six stores in July 2021, has expanded nationwide through repeated discussions with local governments in which we operate direct stores.

We will actively promote FANCL's unique recycling philosophy which has three elements. Firstly, reducing the burden on the natural environment; secondly, encouraging diversity and inclusion (the utilization of people with disabilities); and thirdly, making a contribution to local communities. Together with the help of many of our customers, we will do our part to create a recycling-oriented society.

Going forward, we will collaborate with the Kirin Group (with whom we have a capital and business alliance) as part of a new challenge to achieve "closed-loop recycling" in which chemical recycling technology is to transform used cosmetic containers into new cosmetic containers.

- FANCL SMILE Co., Ltd: A special subsidiary established in 1999 to support the independence of people with disabilities.

RENEWABLE

We use materials that have a low environmental impact, such as plant-derived and recycled plastics.

A first for Japan's cosmetics industry: The reuse of PET bottle caps

(Using recycled plastic derived from the caps of PET bottles)

FANCL Group entered into a capital and business alliance with the Kirin Group in 2019, resulting in various ongoing joint development projects. One of these such projects involves the repurposing of recycled resin derived from plastic bottle caps as part of the polyethylene spout mechanism used for our Skin Clear Cleanse Oil Eco Pack containers, and as a first in Japan, we have utilized the same material for our cosmetics containers . As a result of these efforts, Kirin Beverage was able to reuse about 30-40% of its manufactured bottle caps, succeeding in reducing the environmental impact caused through waste. In addition, ATTENIR has been able to reduce the amount of plastic used for its Skin Clear Cleanse Oil packs by about 40% through the repurposing of recycled resin.

Use of recycled plastics through chemical recycling

As of the end of March 2023, PET containers used for FANCL cosmetics (the main container bottles) are entirely made from chemically recycled PET materials. (Excluding some products)

We also use recycled and plant-derived plastics for the caps and pumps (PP and PE) of our basic cosmetic containers.

Through these efforts, we have significantly reduced our CO2 emissions.

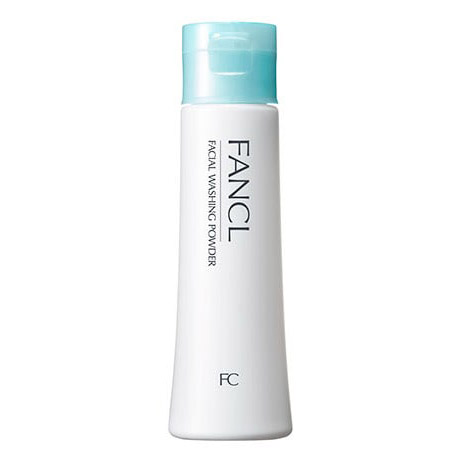

Use of plant-derived plastics

Plant-derived plastics are now exclusively used for our main products such as facial cleansing powder bottles, whole body foam wash, and Baby Moisture Milk in our Baby Care line.

Attenir uses a plant-derived plastic made from sugar cane in the containers of its hair care product Salon Premium Shampoo Scalp & Volume launched in February 2023.

BABY MOISTURE MILK

Use of environmentally friendly paper (in addition to the container and packaging materials used for products)

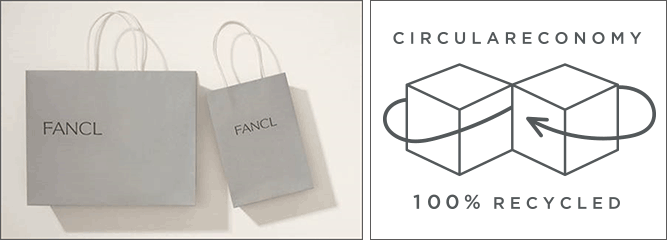

To support forest conservation, the FANCL Group will switch to 100% environmentally friendly paper※1 as a container packaging material by the fiscal year ending March 2026.

In addition to our products, we use certified forest paper for our information magazines and online and catalogue sales. We are adopting environmentally friendly paper for various printed materials and sales promotion materials.

From April 2023, all FANCL direct stores will use paper bags that adopt the circular economy model※2. This initiative is the first in the cosmetics industry※3.

- Certified paper, non-wood paper, recycled paper, etc.

- The circular economy is the name given to an economic system in which products and raw materials that are discarded in conventional economies are treated as resources and recycled and reused, to create a system of circulating resources.

- FANCL research

Handling of microscopic beads

We always consider various issues related to the use of plastics when selecting materials to include in our products.

As such, FANCL and ATTENIR do not use microbeads in the development of their rinse-off cosmetic products.

In recent years, there have been concerns about the environmental impact of microbeads, which are a type of exfoliating agent that can be used to address skin staining and to remove dead skin cells, and regulations regarding their use are now being implemented around the world.

This decision is part of FANCL Group's efforts to continue creating products that are environmentally friendly.