We strive to improve our rate of recycling and reduce waste in order to make effective use of limited resources.

Initiative report

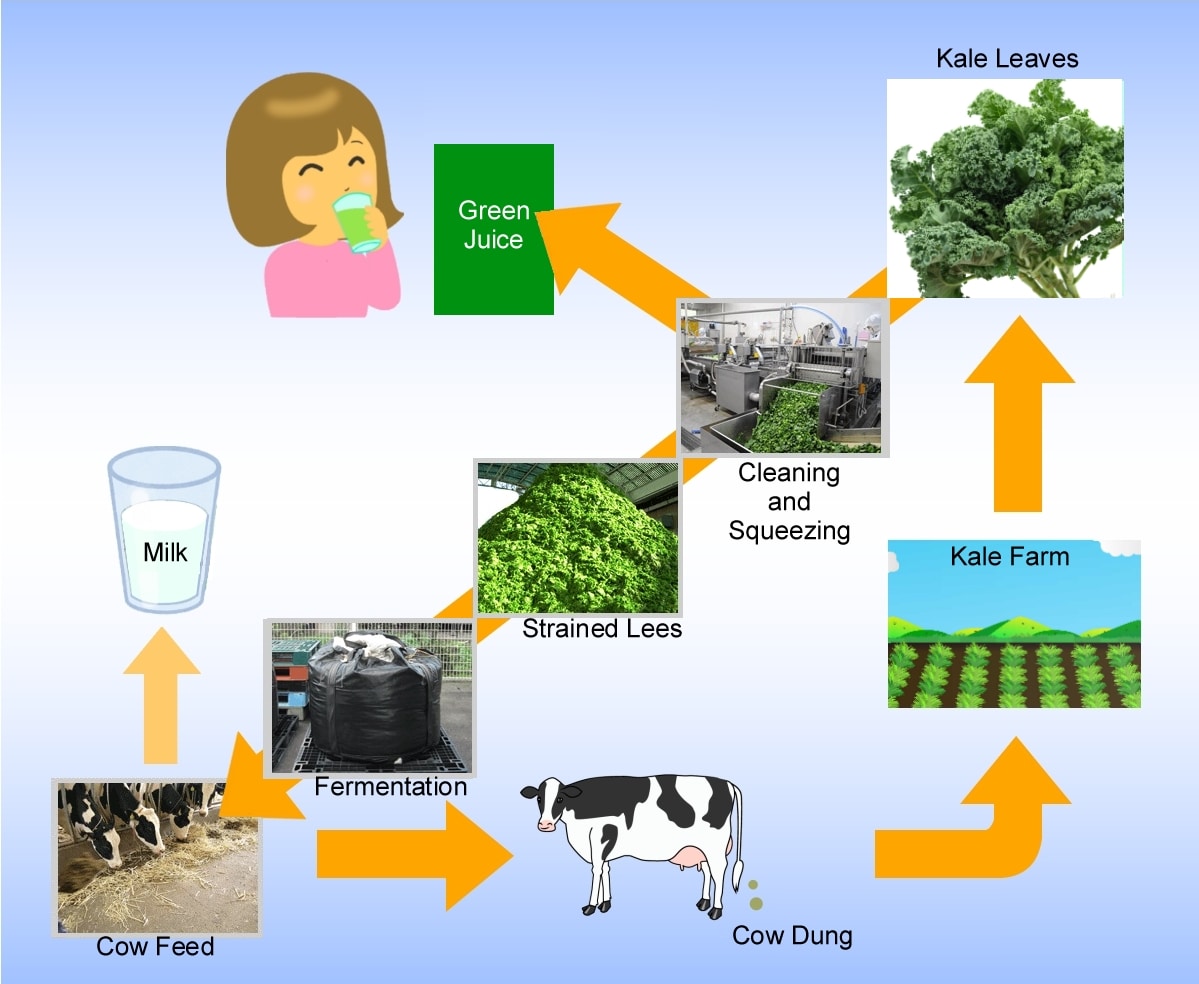

Kale Juice

We process kale to produce kale juice at a factory in Seiyo, Ehime Prefecture. An issue with kale juice is that a lot of remnants are left over from the production process. It was because of this that we started to research how kale dregs could be used in feed for cattle, given the high level of dairy farming in this area of Japan. After two years of trial and error, we learned how to use it in high quality feed for cattle. At the same time, the manure produced by these cows is used to fertilize the fields, where, in turn, more nutrient-rich kale is grown, which can then be processed again into kale juice, achieving a complete recycling of materials. The process has been certified by Ehime Prefecture as a “Superior Model for Resource Recycling.”

Recycling of sorted rice

The raw material of FANCL Hatsuga Genmai is brown rice, an agricultural product. Due to poor growth and climatic conditions, brown rice that is unsuitable for production inevitably gets mixed in during harvesting. Rice that is discolored due to immaturity or weevils is removed from the manufacturing process. It is a waste of resources to simply throw away the sorted rice that is not suitable for our Hatsuga Genmai products because people will not eat it. Therefore, this sorted rice is effectively utilized by mixing it with chicken feed.

Aiming to develop a more SDG-friendly employee cafeteria

Since April 1, 2022, we have been working with a recycling company to compost food waste from the employee cafeteria for effective utilization as a resource. The conversion of food waste into a resource, as well as resource recycling, leads to a reduction in waste. We are also working with recycling companies to utilize food waste generated at the employee cafeterias in the FANCL Research Institute and Iijima Building for biogas power generation※.

Biogas power generation is a method of generating electricity by creating biogas from organic residues such as food waste and wood waste, and burning the biogas. It does not emit large amounts of greenhouse gases compared to when fossil raw materials are burned, and is effective against global warming.

Reducing plastic usage

The FANCL Group is also actively involved in recycling of plastic containers.

Please click here for more information on reducing plastic usage.

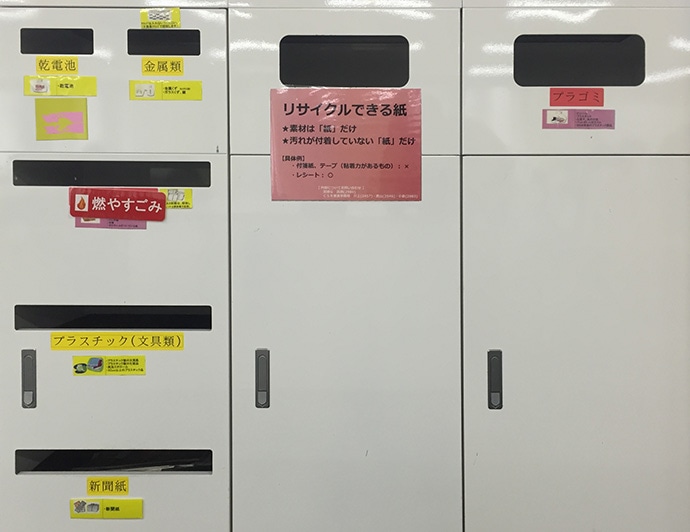

Collection of Separated Refuse

FANCL is working to increase its rate of resource recycling by separating and collecting used paper and paper beverage cartons in its offices. We have set up separate refuse collection boxes in our Head Office buiilding and separate refuse into burnable waste, recyclable paper, plastic waste, metal waste, used dry cell batteries, and other categories. We also separate and collect old newspapers and magazines, used paper , and shredder waste, as well as food waste, beverage cartons, cans, glass bottles, and plastic bottles from the office kitchen, and sort them into recyclable items and that those that should be disposed of.

Used plastic bottle caps are given to NPOs that collect them, and are used to purchase polio vaccines* for children around the world.

Polio, or poliomyelitis, is an infectious disease caused by the poliovirus that mainly affects children under the age of five. In Japan, vaccines are given to infants up to 18 months old, but in some developing countries, vaccination is insufficient, and support is required.

Employees are made aware of the refuse sorting situation and sorting rules at FANCL through events where they experience the sorting process themselves. In doing so, employees also learn the reasons for correctly sorting refuse and the importance of resource recycling.

FANCL employs a recycling company to collect waste cooking oil from the company cafeteria. This is then used as a raw material for safe and environmentally friendly biofuel. In addition, we are also tackling waste reduction by having recycling companies collect used cardboard and raw materials containers, rather than dispose of them, and reusing these materials for delivery to and from raw materials manufacturers.

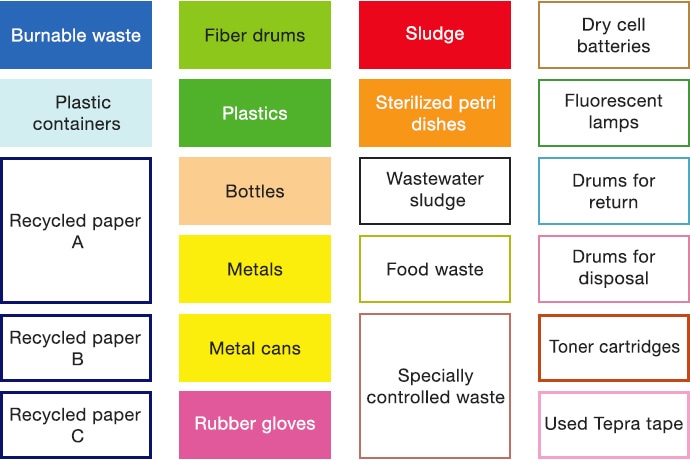

Garbage sorting at the plant

As a pioneer of FANCL Group's "environmentally friendly factories," the Shiga Plant installed FANCL Group's first solar power generation system in 2011, reducing electricity consumption and CO2 emissions. The plant is also actively working to reduce waste, and have achieved zero waste by utilizing recycling through the separation of 22 types of waste. This initiative is being horizontally spread to other company-owned factories, contributing to the reduction of business-related waste in the FANCL Group.